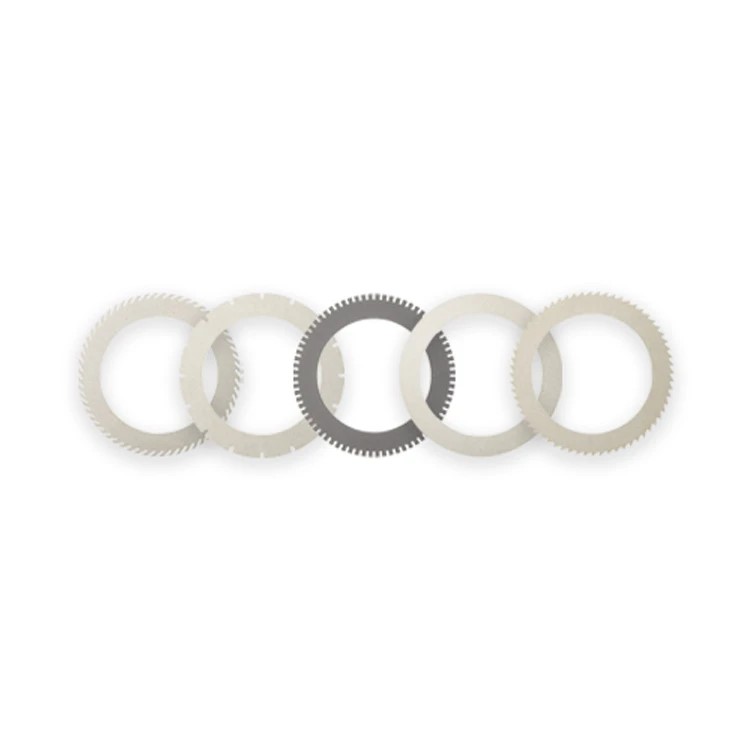

High-Precision Dicing Blade for Wafers and Substrates

Nickel Bond Dicing Blade – DS Type

The DS-Type nickel bond dicing blade is the ideal solution for precise, fast, and efficient singulation of wafers and substrates. With high rigidity, outstanding wear resistance, and excellent sharpness, the DS-Type blade delivers clean cuts and increased productivity. This specialized blade series is designed to meet the demanding requirements of the semiconductor and electronics industries, helping to optimize your manufacturing processes.

Key Advantages of the DS-Type Blade:

- High Precision at High Cutting Speeds:

Thanks to its excellent cutting ability and rigid structure, the DS-Type blade delivers outstanding precision even at high speeds. Perfect for challenging materials such as ceramics, hard substrates, and brittle components. - Outstanding Wear Resistance:

The DS-Type blade offers excellent wear resistance, resulting in a longer service life and reduced tooling costs due to fewer blade replacements. - Versatile Application:

With various slit shapes and customizable options, the DS-Type blade is suitable for a wide range of materials and applications—from chip LEDs and ceramics to delicate brittle substrates. - Cost Reduction Through Increased Yield:

The blade’s tight cutting tolerances and ability to precisely cut even extremely small through-holes improve product quality and help maximize yield, reducing overall production costs.

Technical Highlights of the Nickel Bond Dicing Blade:

- Applicable Materials:

Raw ceramics, chip LEDs, various substrates, hard and brittle materials - Maximum Speed:

30,000 rpm with UV tape (PET type), 18,000 rpm with UV tape (PO type) - Processing Speed:

150 mm/s for through-hole cutting, 50 mm/s for electrode cutting - Adjustable Concentration Levels:

3 different concentration levels to meet specific cutting requirements

Applications of the DS-Type Blade:

- Through-hole cutting

- Electrode cutting

- Wafer and substrate processing

Benefits of the DS-Type Nickel Bond Blade:

- High cutting speed and precision for optimized production times

- Versatile: Ideal for a wide range of materials and applications, from ceramic substrates to LED chips

- Longer blade life and reduced operating costs thanks to wear-resistant properties

- Increased yield and lower costs through improved cutting tolerances

Optimize your production with our high-precision blades.