SBS Balancing – The Solution for Control & Precision

Dynamic Balancing Systems for Machine Tools

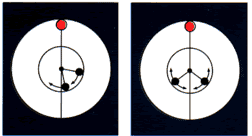

Industrial production also places high demands on grinding machines. Unwanted vibrations of the grinding wheel relative to the workpiece surface lead to surface defects, so-called chatter marks. Shape and dimensional accuracy also suffer when the rotating tool exceeds important tolerance values. Imbalances not only have negative effects on product quality. They can also affect the bearing life of the machine. The loss of mechanical energy also leads to increased power consumption.

In addition, customers are demanding higher accuracy from the workpieces they produce, while at the same time cycle times are shortening. Therefore, it is important to keep the vibrations of the grinding wheel low. In operation, sensors must be able to quickly detect rotational deviations and pass this information on to the operator or automated to other machine components in production.