Surface measuring

When talking about measuring a surface, it is likely that it’s roughness is a consideration.

You can also gain an overview of quality assurance for surfaces on the following page. Please contact us if you want to make a request or have any questions.

You can also click directly on one of the sections:

What is surface roughness?

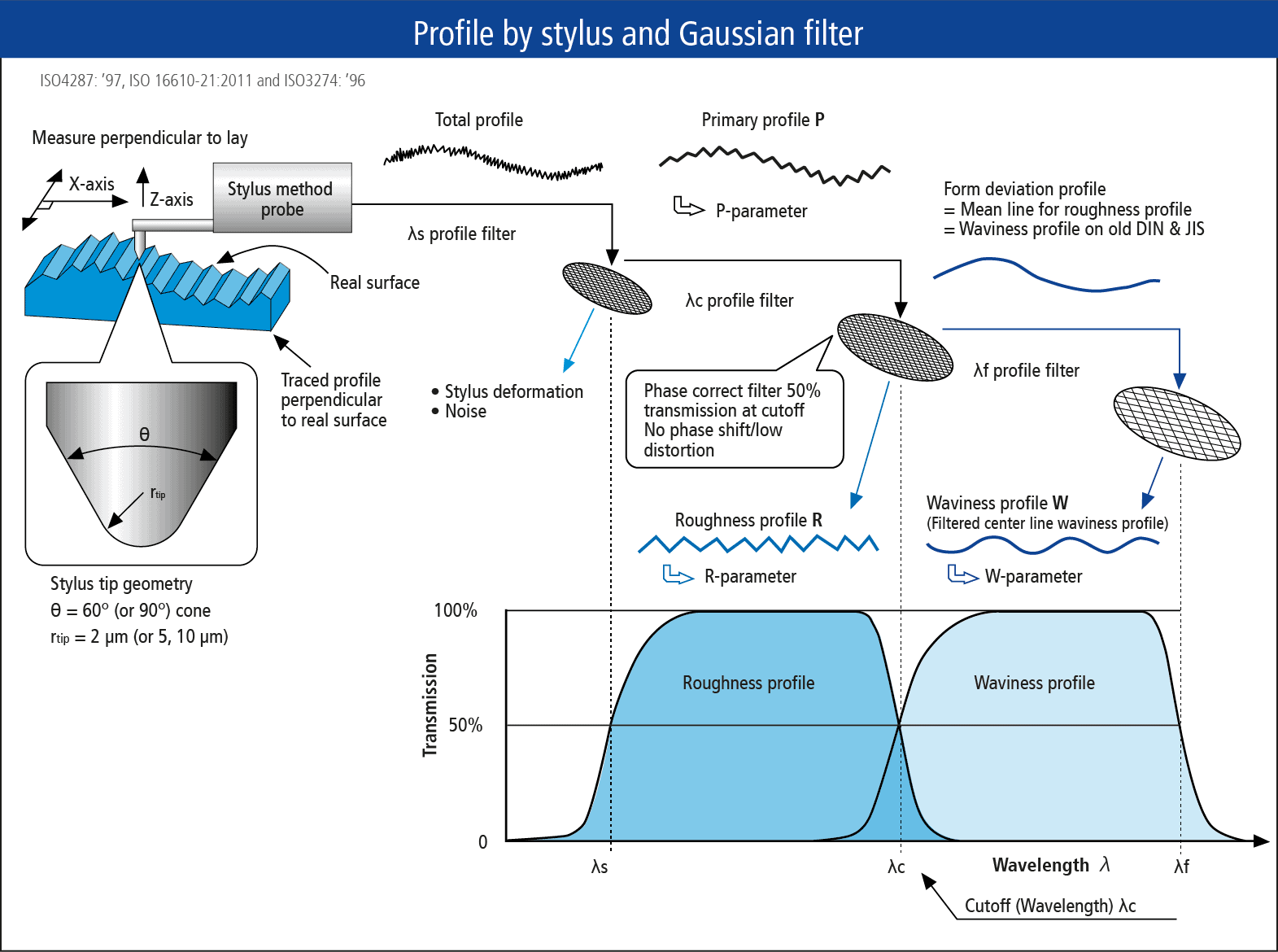

Roughness is a component of surface texture, and is irregularities on a surface resulting from unevenness. These so-called surface deviations arise from the effect a machining or finishing process has on the surface. They are categorised into course and fine. Shape and position deviations are categorised as course form, waviness and roughness are categorised as fine form:

- Shape: Deviations in long periods or non-cyclical deviations

Possible causes: Error in the in the machine tool axis, incorrect clamping of the workpiece, uneven wear and tear. - Waviness: Surface structure with longer intervals of irregularities.

Possible causes: Vibration in the machine tool or workpiece. Tooling problems during the manufacturing process of parts. - Roughness: Irregularities with shorter intervals

Possible causes: unwanted rough surfaces are caused by cutting tool markings, grinding wheel/ abrasive grain size.

Not sure which measuring instrument fits your needs? Filter by the parameters you need and see the solution that’s right for you. Contact us in terms of questions or requests.