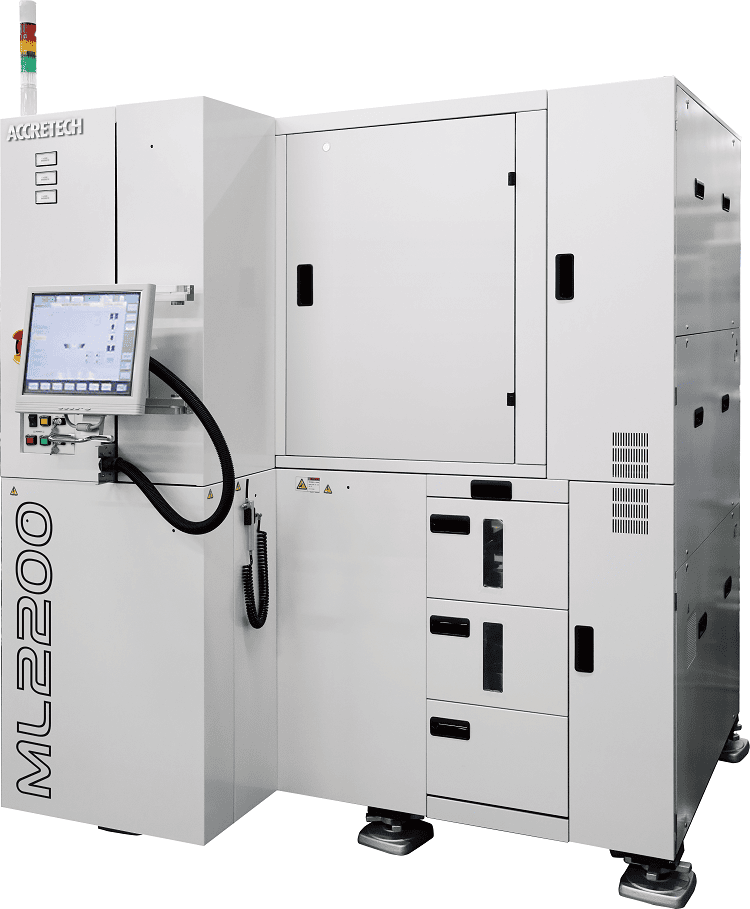

Fully Automatic IR Laser Dicing Machine for Φ200 mm Wafers

ML2200 – Maximum Precision and High Speed for Your Wafer Processing

The ML2200 is a fully automatic dicing machine designed for high-precision processing of Φ200 mm wafers. Featuring a powerful IR laser and an innovative dry dicing process, this machine offers an efficient solution for processing MEMS devices and other delicate components without the need for water. Maximize productivity, reduce costs, and increase yield — all with a single, high-performance system.

Key Benefits of the ML2200:

- Contactless Dicing for Maximum Precision:

IR laser technology enables precise processing without direct contact with the wafer surface, preventing damage to sensitive substrates. This results in superior quality and minimal reject rates. - Dry Process for Sensitive Devices:

The dry dicing process makes the ML2200 ideal for MEMS and other sensitive materials that cannot tolerate mechanical stress or moisture. Your products remain intact without requiring additional liquids or chemicals. - Yield Boost Through Narrower Dicing Cuts:

By reducing the dicing cut width from 90 μm to just 20 μm, you can increase chip yield by up to 20%. This leads to higher profits and faster return on investment. - Maximized Productivity at High Speeds:

With a dicing speed of up to 800 mm/s and a stable, high-rigidity platform, the ML2200 significantly reduces processing time and helps you meet production targets faster. - Versatile Configuration Options:

Tailor the machine to your specific production needs. Optional features such as internal Class 100 cleaning and wafer thickness measurement help you further enhance quality and efficiency.

Technical Highlights:

- Maximum Wafer Size: Φ200 mm

- Processing Method: Frame handling

- X-Axis Speed: 0.1 to 1,100 mm/s

- Y-Axis Resolution: 0.0002 mm

- Positioning Accuracy: Within 0.002 mm / 210 mm

- Dimensions (W × D × H): 1,640 mm × 1,340 mm × 1,800 mm

- Weight: 2,000 kg

Why the ML2200 Can Optimize Your Production:

- Lower production costs thanks to high yield and reduced material usage

- Fast, precise dicing processes for consistent, reliable manufacturing

- Adaptable to various wafer thicknesses and applications, such as MEMS and other sensitive devices

- Water-free operation for a more environmentally friendly and cost-effective process

Learn more about how the ML2200 can boost your manufacturing efficiency

Explore Our Full Product Line

Download the product overview to see how our solutions can support your needs.