Semiconductor Manufacturing Solutions – Precision by ACCRETECH

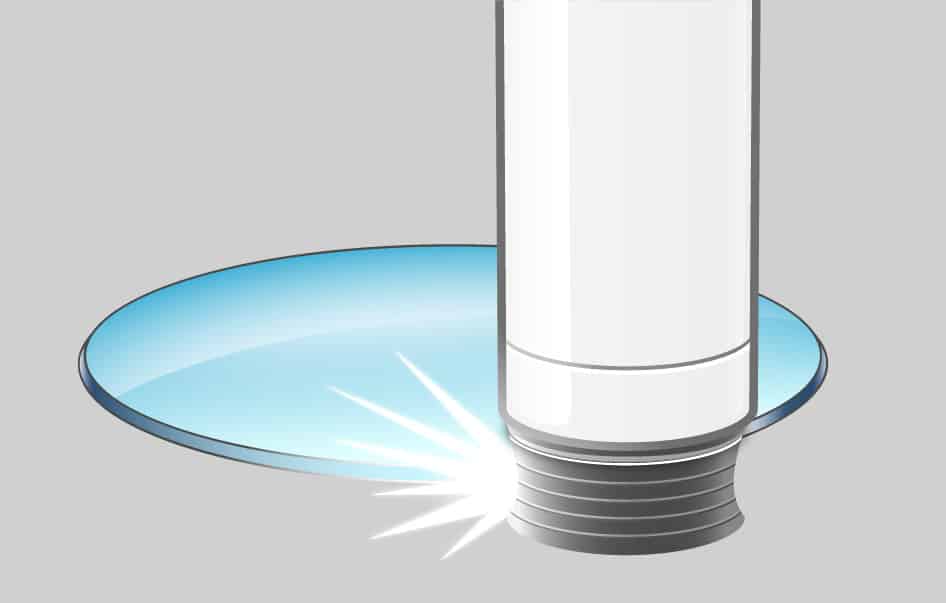

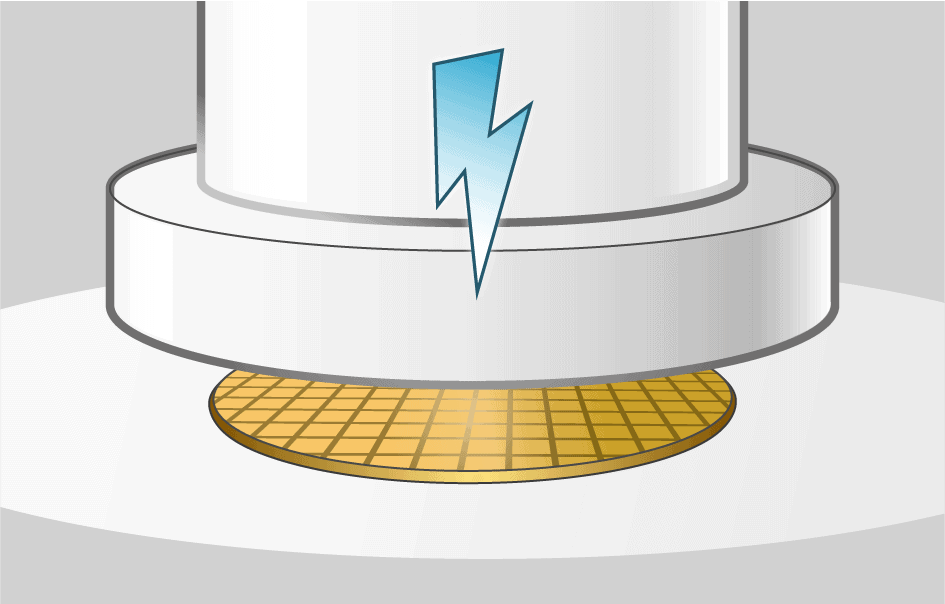

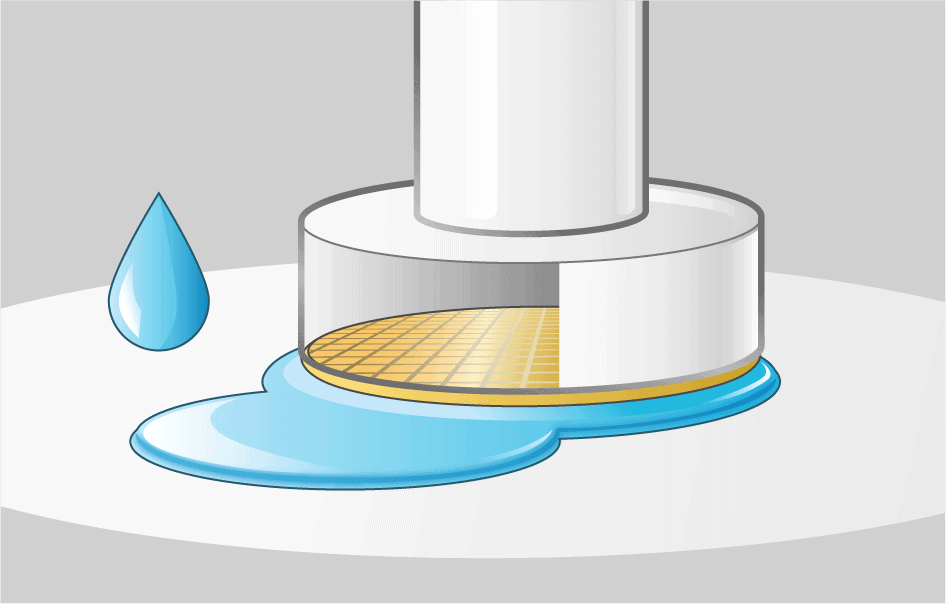

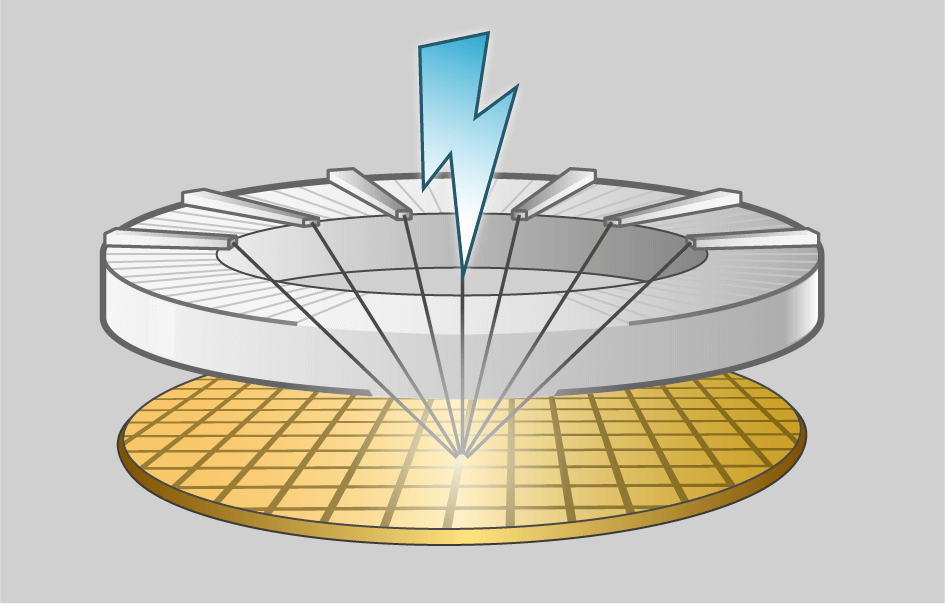

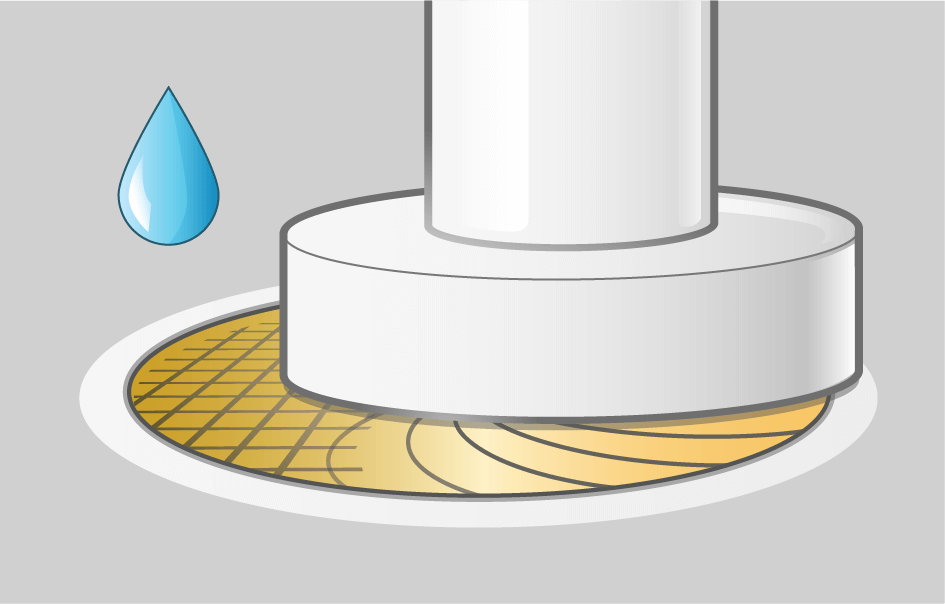

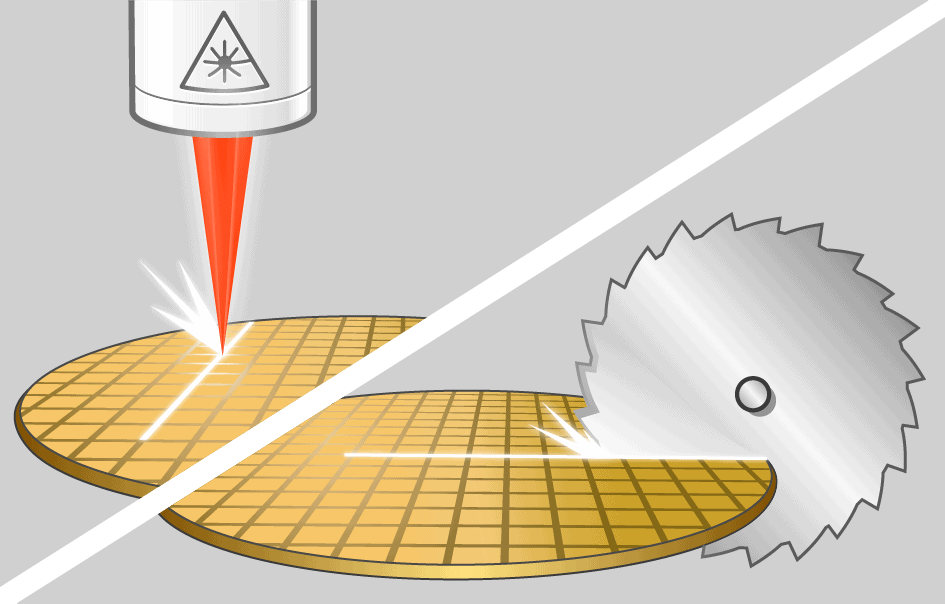

Whether silicon, GaN, or sapphire: ACCRETECH supports your wafers from edge grinding to dicing. With high-tech systems for grinding, polishing, dicing, CMP, and probing – modular, fast, and compact.