CMP Equipment for the Highest Demands in Semiconductor Manufacturing

What is CMP (Chemical Mechanical Planarization)?

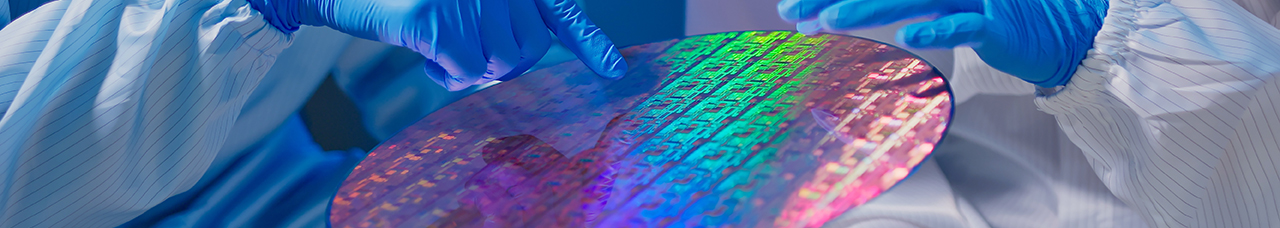

CMP — Chemical Mechanical Planarization — is a key process to create smooth, planar surfaces on semiconductor wafers. Especially for low-k materials or material stacks with varying hardness, CMP is indispensable, as purely mechanical methods would cause steps or defects.

Why Choose ACCRETECH CMP Systems?

Our ChaMP series CMP machines offer:

- Superior surface quality through precise polishing technology

- Modular design for maximum flexibility

- Automated processes with integrated wafer handling and cleaning