Fully automatic grinder for hard materials up to 200 mm – with dual-axis precision and integrated wafer cleaning.

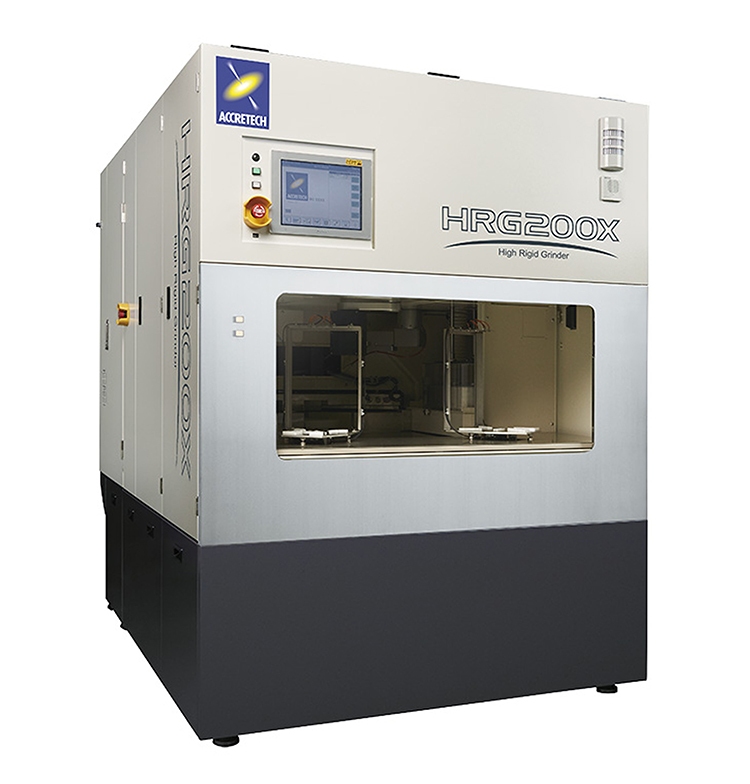

HRG200X

The HRG200X is a fully automatic high-rigidity grinder designed for hard semiconductor materials up to 200 mm in diameter. With its ultra-stable construction and dual-axis technology, it minimizes grinding damage and shortens processing times — while maintaining high accuracy and low operating costs.

Equipped with an integrated cleaning unit, the HRG200X prevents silicon dust from drying onto the wafer surface. The automatic cleaning function ensures consistently clean processing. The result: a flawless mirror-finish surface, ideal for subsequent manufacturing steps.

Key Benefits of the HRG200X:

- High-speed grinding for wafers up to 200 mm

- High process stability thanks to vibration-damping design

- Integrated cleaning system to remove silicon dust

- Reduced grinding damage due to dual-axis technology

- Short cycle times, low operating costs

- Ultra-precise surface grinding (mirror finish)

- Ideal for advanced semiconductor production with SiC, GaN, or sapphire

Choose the HRG200X for maximum precision and efficiency

Explore Our Full Product Line

Download the product overview to see how our solutions can support your needs.