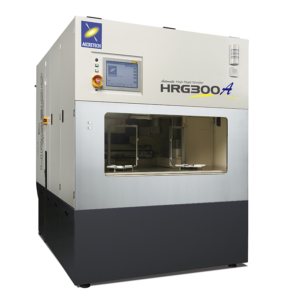

High Rigid Grinding

Precision Grinding for Hard Wafer Materials

As alternative semiconductor materials like silicon carbide (SiC), gallium nitride (GaN), and sapphire become increasingly important, the demands on wafer grinding continue to rise. ACCRETECH’s High Rigid Grinding systems are engineered specifically for these ultra-hard materials. Thanks to their extremely rigid and low-vibration design, they ensure maximum grinding precision and process stability – even with ultra-thin wafers.

Key Benefits of High Rigid Grinding:

- Maximum Precision: Accurate material removal even on ultra-thin wafers

- Increased Throughput: Enhanced surface preparation enables faster wafer dicing

- Reduced Tool Wear: Optimized grinding processes extend tool life

- Minimized Risk: Lower probability of microcracks and chipping

- Process Integration: Ideal for downstream steps such as edge grinding or CMP