ACCRETECH EUROPE – Industrial Metrology and Semiconductor-Equipment

ACCRETECH, the brand from Tokyo Seimitsu, was founded in 1949 in Tokyo and today is one of the leading providers of industrial measuring technology and the latest equipment for the semiconductor industry with more than 3,000 employees worldwide. ACCRETECH (Europe) GmbH has been firmly entrenched in the European market since 1989.

ACCRETECH (Europe) GmbH, headquartered in Munich and with locations in Italy, France, the UK, Hungary and Turkey works with sales and service partners throughout Europe. This means you always have a contact partner locally who can help you to implement integrated solutions for quality assurance in production processes and for semiconductor production.

Success Story

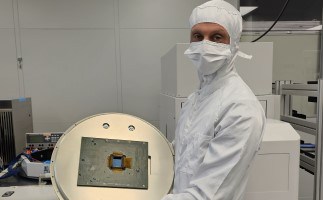

ARRI sets up internal wafer inspection

ARRI Cine Technik is known as the leading producer of high-end film cameras and a key to their success is their commitment to the highest quality standards. As the image sensor is a critical component in every camera, ARRI decided to introduce its own in-house inspection process. The quality check should occur very early in production before the sensors are mounted into the camera. A precise and automated wafer handling system was therefore required, and ARRI Cine Technik approached wafer processing specialist ACCRETECH for solutions.

Whitepaper

Reliable quality management for medical products

In order to meet the tight tolerance limits and standards in the manufacture of implants, metrological solutions can support medical technicians in ensuring quality. In our new whitepaper, you can find out everything you need to know about metrology methods for ensuring the highest quality.

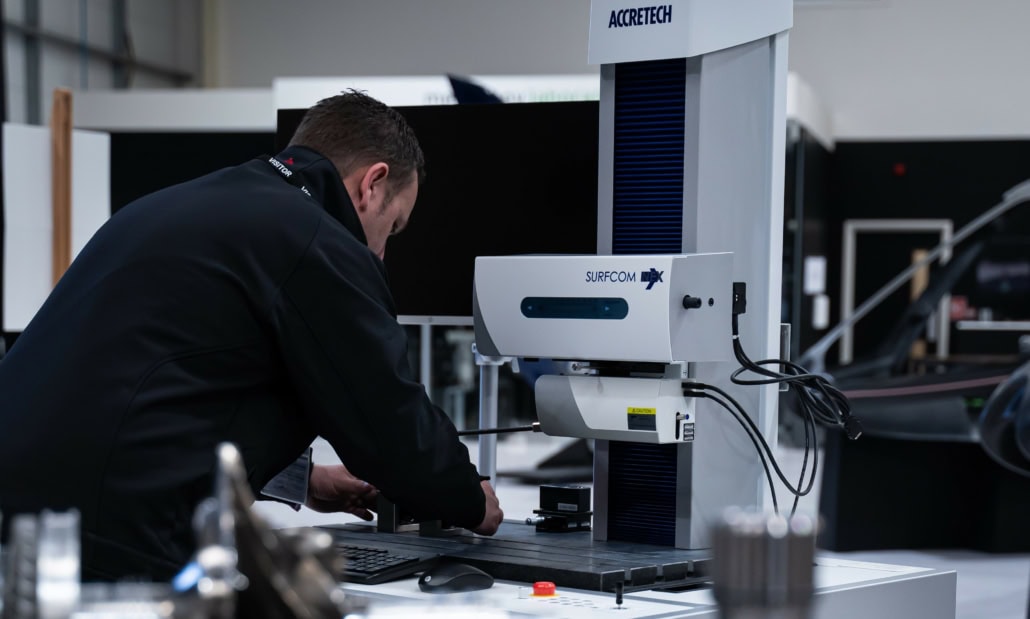

Customer story

Hill Helicopter’s quality ‘takes-off’ with ACCRETECH

The recent installation of an ACCRETECH SURFCOM NEX surface and contour measuring machine at the premises of Hill Helicopters illustrates the advantages aerospace manufacturers gain when they are able to achieve rapid, high-precision inspection results.

High-precision measuring technology for surface, form, and contour

Every detail counts when it comes to workpieces in the automotive industry, aviation and medical technology. Deviations from prescribed tolerances can cause components not to function properly or to wear out faster. Careful quality assurance is the only way to detect whether a workpiece meets all the specifications in time. Every deviation detected by production metrology in surfaces or profile properties from the prescribed tolerances will help to prevent errors and reduce costs.

We offer high-precision industrial measuring technology for the quality assurance of your workpieces and your production process. Our measuring instruments are used by notable companies in the automotive supply industry and others for quality assurance. Many of our measuring instruments are patented.

Our instruments facilitate quality measurements for surfaces, contour and profiles.

All instruments are easy to install and use. Thanks to a modular building block system, our measuring instruments can be adapted to the respective customer’s needs. Our production measuring instruments are complemented by use-friendly software that can be used to graphically evaluate and record the measurement result.

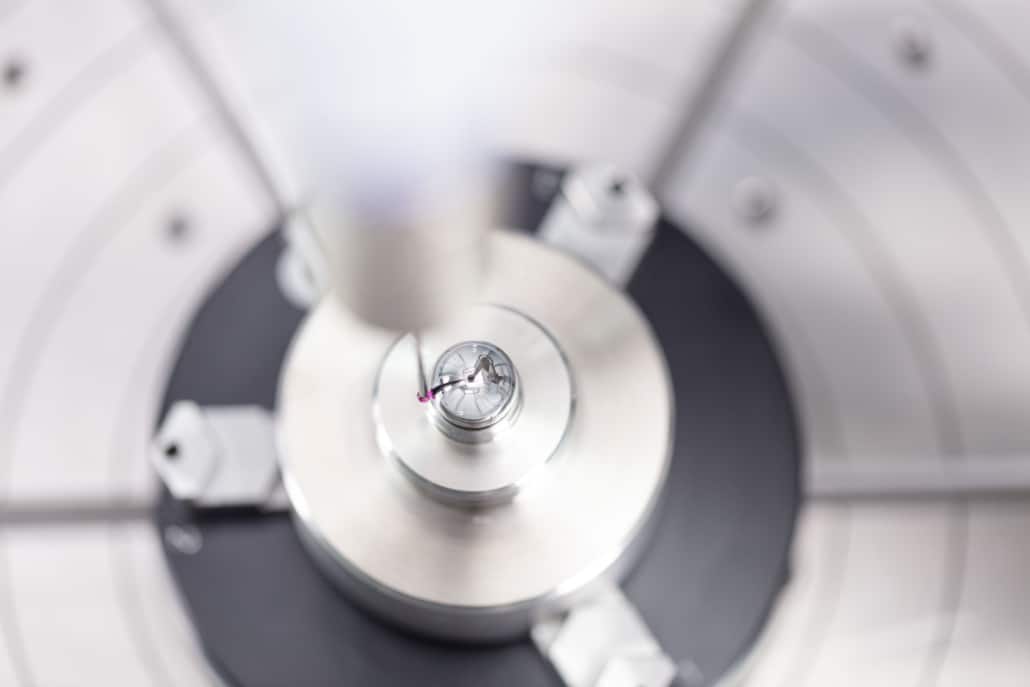

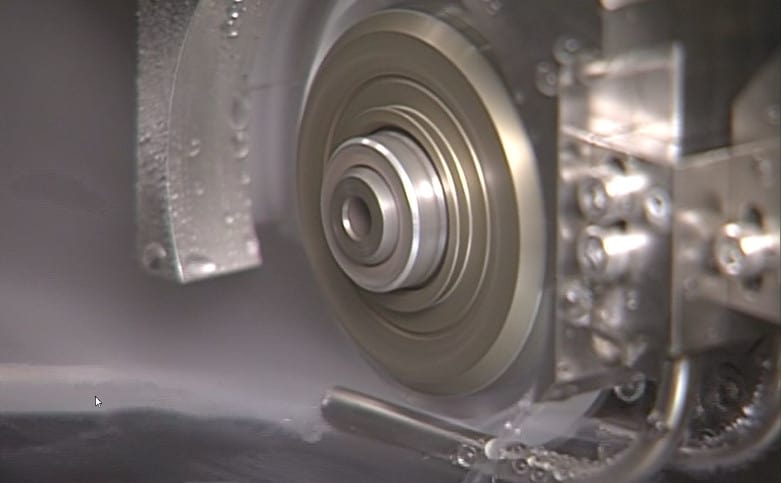

Semiconductor systems for efficient microchips

We produce semiconductor systems for the semiconductor industry. In order to manufacture a modern micro-processor from the silicone harvested from the raw quartz sand, a number of automated work steps are required. The finished discs made of high-purity silicone are used as wafers in micro-system technology, forming the basis for modern micro-chips.

Semi-conductors are increasingly used in more areas of daily life. As digitisation expands, so do the requirements for semi-conductor and wafer requirements. Extremely small, high-efficiency micro-chips are needed for assistance systems in cars, facial recognition, IoT or even Smart Homes. The basis for these micro-chips is extra-thin, extra sturdy and completely flawless wafers with uneven surfaces of only a few nanometres. These wafers cut into individual chips called dice in the final step.

Our semi-conductor systems represent important steps in the semi-conductor manufacturing process. They can be used to produce the sustainable wafer quality required by the semi-conductor industry. All systems work with high precision and high speed.