For when things need to be ultraprecise

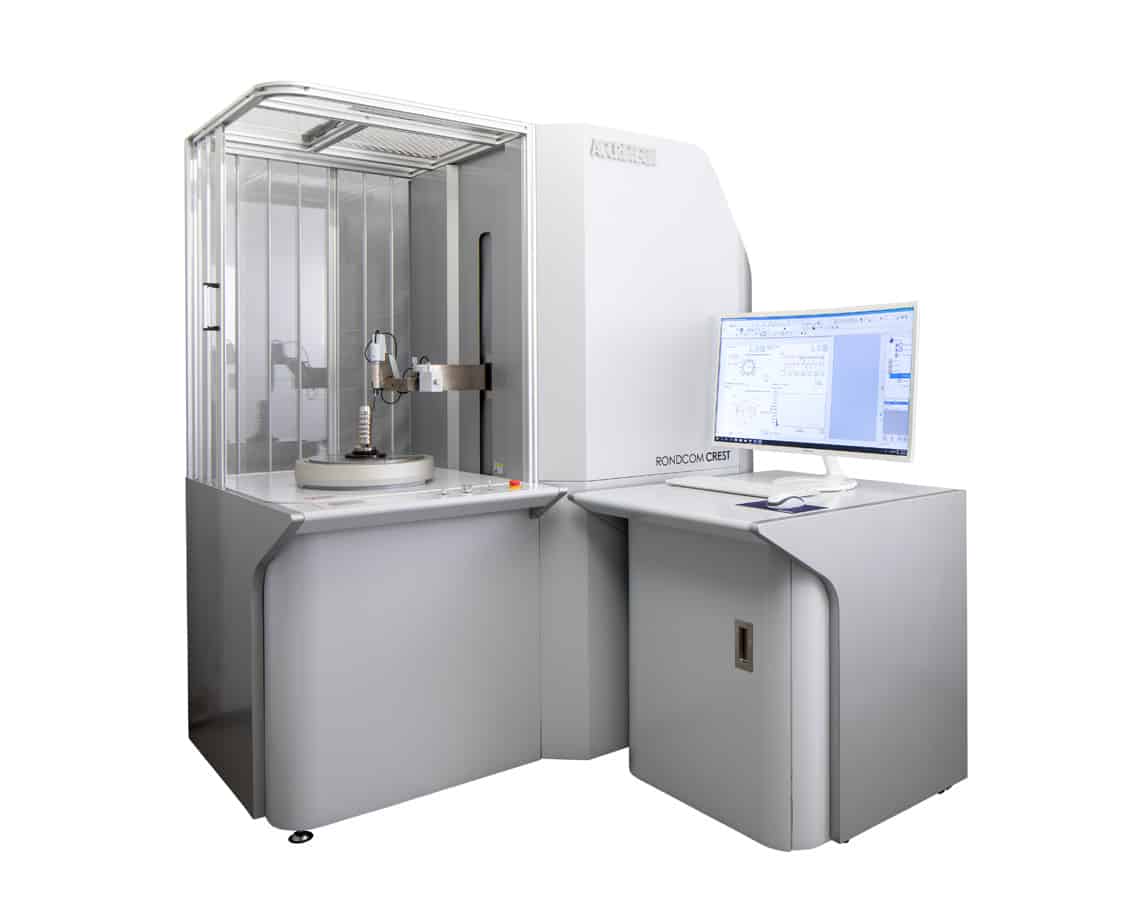

The RONDCOM CREST profile measuring instrument from ACCRETECH sets new standards in its class when it comes to accuracy.

The demands on the accuracy of roundness measurements are increasing. One example of this is the automotive industry, which is working to further improve fuel efficiency. For instance, injection modules must be manufactured with ever greater precision in order to guarantee ignition in diesel engines. High-precision roundness measurements are required for many rotationally symmetrical components such as drive shafts, axles, wheel hubs and brake discs – even outside the automotive industry.

Production managers and calibration laboratories demand ever more precise measuring technology

Production managers thus demand measuring technology from quality assurance to ensure the high-precision manufacturing of rotationally symmetrical components. However, the profile measuring instruments available in the precision measurement room are increasingly reaching their physical limits in terms of accuracy. This is also true of profile measuring instruments in calibration laboratories, which certify the metrological traceability of the reference standards for profile measurement.

Highest roundness accuracy of (0.01+3H/10000) μm

ACCRETECH has therefore launched the RONDCOM CREST, a new high-end profile measuring instrument, on the market, which is the most accurate roundness and cylindrical profile measuring instrument in its class in terms of its values: It offers roundness accuracy of (0.01+3H/10000) μm and smoothness accuracy of (0.02+3R/10000) μm. Compared to the previous generation R65B, ACCRETECH has increased repeatability by 0.3 μm. The straightness accuracy of the Z measuring axes of 0.05µm/100mm and a resolution of 0.001 µm is not achieved by any other form measuring instrument on the market. This is also helped by the fact that the probing force setting is set within a range of 4 to 15 mN by the integrated ACCTee analysis software.

In addition, the high-end measuring instrument has a counter-rotating diameter measuring function. This enables extremely precise measurements of diameters with a repeatability of 0.3 μm. An important prerequisite for this is the additional motorised Y-axis, which ensures that measurements are always automatically taken at the highest point.

For the first time, the RONDCOM CREST can also be used to perform high-precision surface roughness measurements in all axes (R, Z and T axis) in one clamping set-up.

New concept for the mechanics of base and axes

To achieve this ultra-high accuracy, ACCRETECH has optimised the mechanical structure of the base and axes of the RONDCOM CREST. A newly developed patent-pending drive and guidance mechanism is used. A non-contact mechanism was selected for both the guide and the drive of the two movement axes: aerostatic air bearings guide the movements of the two axes (R and Z). The aligning table is also attached to a rotary air bearing, which guides the high-precision rotary movements.

Compared to plain bearings, air bearings operate without contact and therefore cause no abrasion, which means that the accuracy of the measuring system remains constant over a long period of time. ACCRETECH has also significantly reduced the vibrations caused by the air bearings with a newly developed nozzle. The measures taken to reduce vibrations above all ensure high-precision roughness measurements.

The two axes are driven by linear drives. Unlike conventional spindles, these motors cause neither noise nor vibration. The noise behaviour for measurements of the Ra value is 20 nm.

As the workpiece rotates, a detector ascertains the deviation of the surface position in order to automatically adjust the force at the back of the measuring arm end. The detector thus enables automatic CNC-controlled measurements. What’s more, there is no need to replace the detector or make manual adjustments, thus saving time for the employees in the measuring room.

About ACCRETECH

ACCRETECH was founded in Tokyo in 1949 and is now one of the world’s leading providers of products for precision measuring equipment and of the most modern equipment for the semiconductor industry. ACCRETECH has been established on the European market since 1989 and now benefits from a comprehensive sales and service network.

Download press release here: as PDF | as Word document