P.E.L. Pintossi face new quality challenges together with ACCRETECH

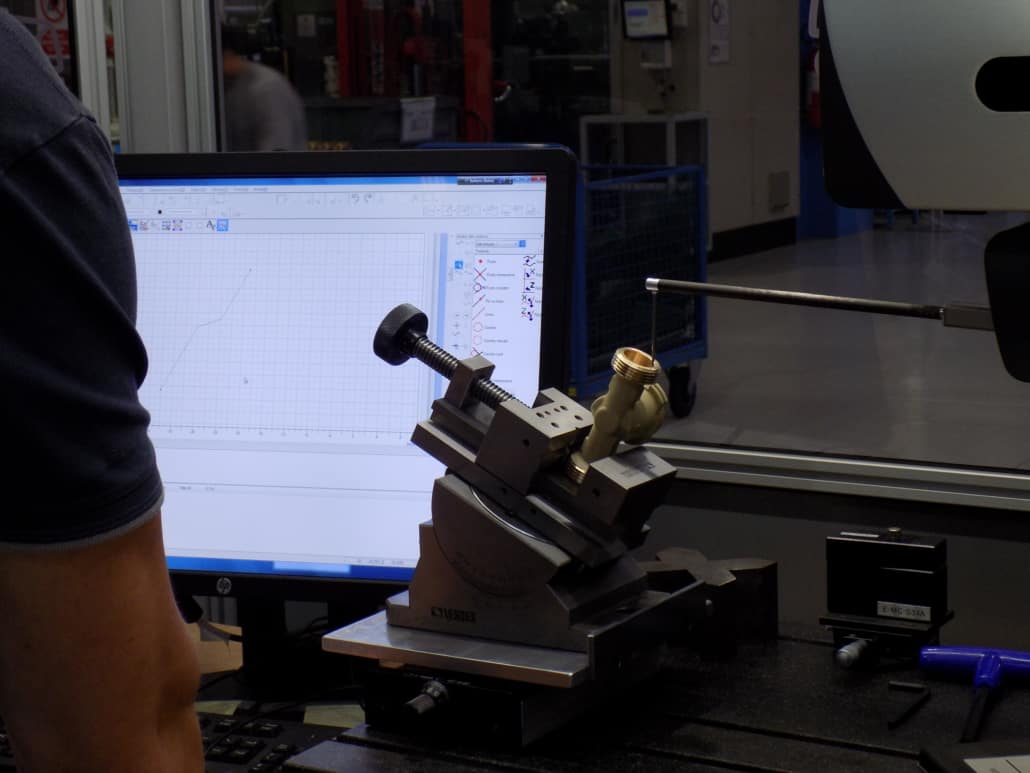

At its factory in Sarezzo (BS), P.E.L Pintossi produce a wide range of components for industry, on which it carries out a large number of processes with increasingly high quality requirements: thanks to the new SURFCOM NEX Profilometer-Roughness Gauges from ACCRETECH, profile and surface control can be carried out directly in production, just a few meters from the machine.

Founded in 1960, P.E.L Pintossi S.p.A. is a leading industrial company within the brass moulding sector, with three cutting-edge production units and a selected network of associated companies. Today, the company is able to meet the demands of customers from different sectors by producing metal alloy components printed and machined to the customer’s design: from valved and thermostatic taps, to ball safety valves and fittings for hydraulic and pneumatic systems, up to the recent development in the automotive field. “Each machined component has specific requirements in terms of dimensional requirements and surface quality: for this reason we need specific machinery such as the new SURFCOM NEX recently purchased from ACCRETECH.” says Mirko Balduchelli, Head of Metrology at P.E.L Pintossi.