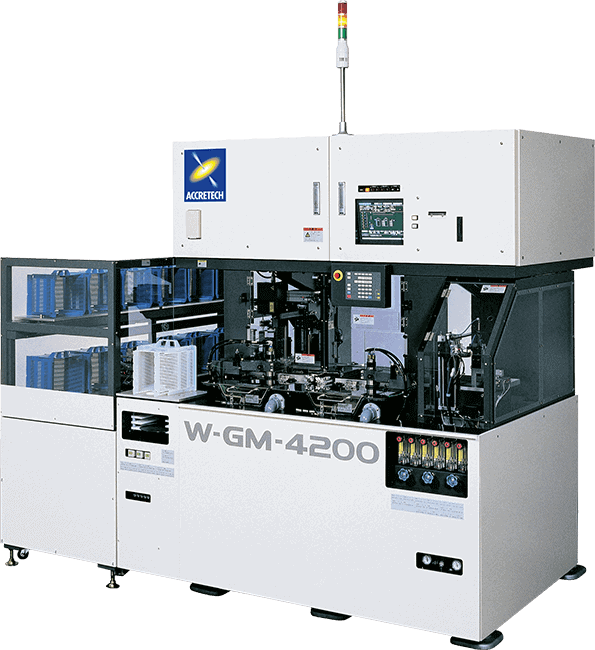

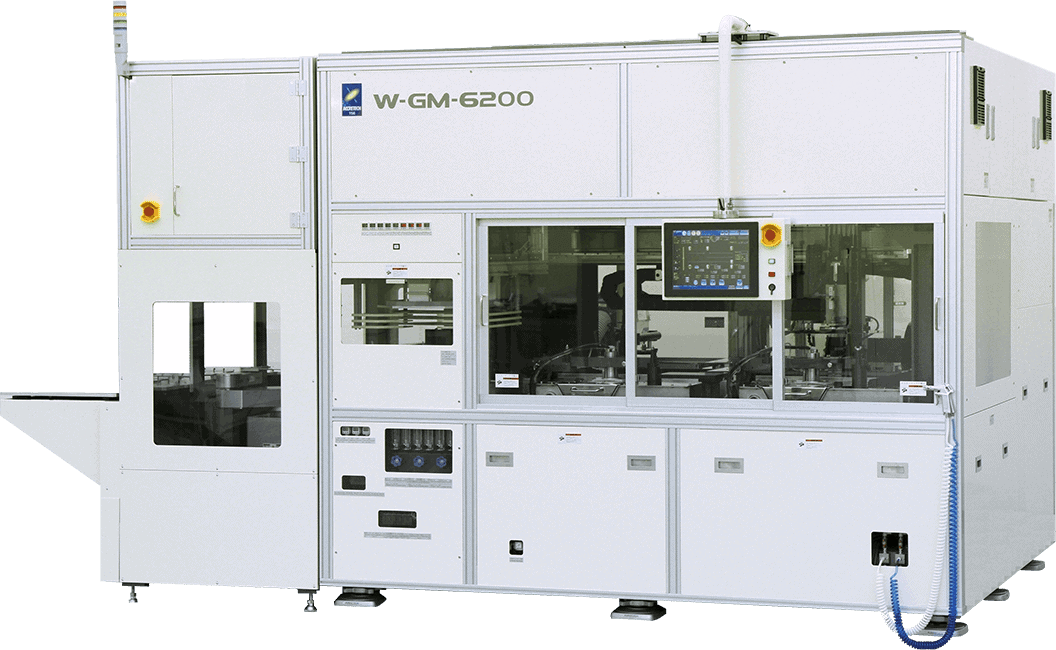

Wafer Edge Grinding

After the sawing of the wafer from the ingot, the wafers have sharp edges which are rounded with a diamond cutter during the Wafer Edge Grinding. The wafers are optimally prepared for the subsequent process steps by the Edge Grinding. It is ensured that no layers applied later are able to flake. Round, smooth polished edges are also important so that the bead of the photoresist surface remains small when spin coating.