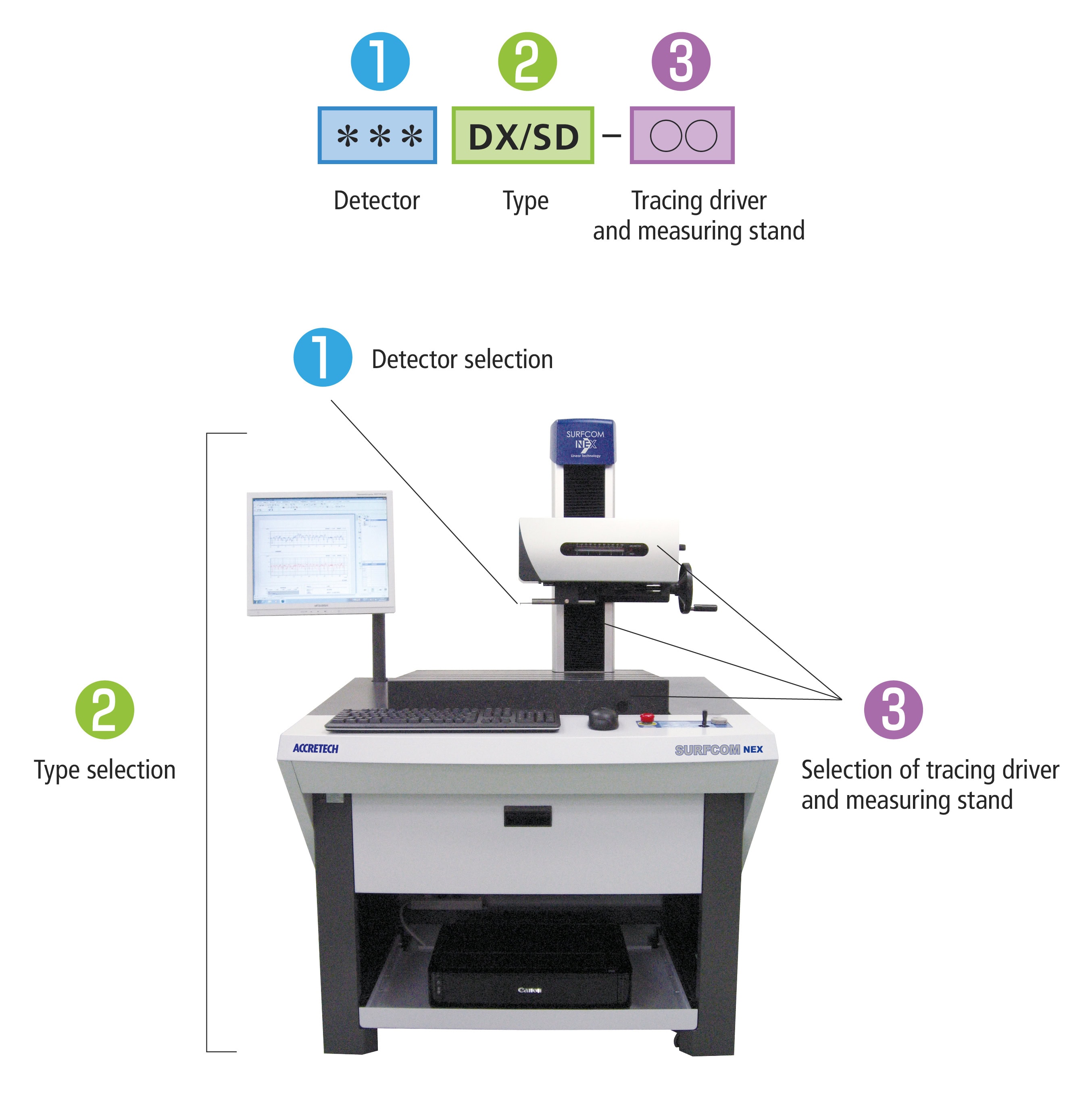

Surface measuring systems

Surface measuring systems for roughness and contour

Surfaces characteristics have a crucial impact on performance, lifespan, visual appearance and ultimately the quality of technical products. That’s why the measurement of surface roughness and quantification in the form of profile, roughness and waviness parameters is of vital importance to many components. In many industries, tolerances regarding surface parameters are narrowing – be it in the automotive industry, aerospace, medical or general mechanical sectors. Surface measurement systems can help to achieve the required quality requirements and tolerances.

Other developments:

- A surface measurement system is no longer found only in the measuring room, but increasingly in the manufacturing environment as well, in order to take measurements directly on, or near to, the production line.

- That’s why when it comes to measurement systems, for some applications, optical measuring instruments giving faster measuring results without touching the part, are seen more frequently

- Surface testing instruments can also be mobile and therefore suitable for flexible use in manufacturing.

- Today, 2D profile sections represent the state of the art when it comes to characterising surface roughness. More frequently, machines that can define the surface in 3D are used to get a more detailed surface characterisation.

- Multi-sensor technology enables roughness and contour to be measured on one measuring instrument, even in a single pass.