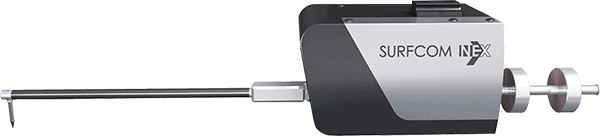

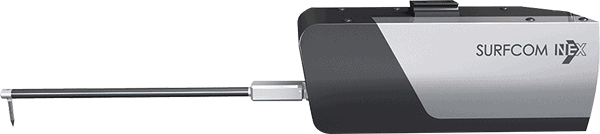

SURFCOM NEX 200

The SURFCOM NEX 200 makes contour and surface measurements possible in a single system with a hybrid sensor.

Hybrid sensor with high resolution and high measuring range at the same time

Combined roughness and contour sensor with Z measuring range up to 26 mm

Deflection with contour probe arm up to max. 52 mm

No need to change the scanning system

Straightness precision (0.05+L/1000) µm

Z accuracy +/- (1.0+2H/100) µm (standard probe arm)

Roughness resolution over the entire measuring range of 0.0009 μm (standard probe arm)

- Fully CNC controlled with teach-in programming

- High traversing speed: X-axis (horizontal) 100 mm/s, C-axis (vertical) 50 mm/s

- Modular structure with sensors for different applications

- Low vibration ensures more stable measurements at high resolution

- Low maintenance thanks to contactless linear drive

- Safety system prevents collisions with the workpiece

- Comprehensive and user-friendly evaluation software

- All instruments available with anti-vibration table (DX version)

- Automated measurement procedures thanks to CNC positioning tables (optional)

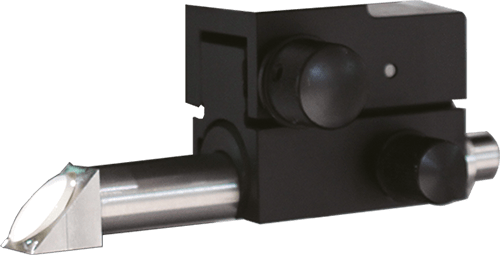

Can be combined with all heads

NEX 001

NEX 030

NEX 040

NEX 200

optical sensor

Area of application

The new hybrid sensor achieves the greatest measurement precision thanks to its two parallel measuring systems integrated in just one sensor. For surface measurements, data is gathered using the high-resolution inductive technology and a glass scale for the large measuring range for contours. This means that, with only one measurement, you can achieve a large measuring range and a very high resolution at the same time.